FOBA Offers Innovative Solution for Laser Marking Medical Devices

FOBA's camera-assisted laser marking solutions are specifically suited to mark high-quality UDI on medical devices.

Based on years of cooperation with manufacturers from the medical industry, FOBA provides an integrated approach to UDI direct part marking. This implies advanced laser marking technology as well as a high level of consulting expertise. "Our customers rely on our sophisticated marking solution to make their medical devices compliant with the UDI-requirements according to the FDA and to the European MDR," says Jeff Kniptash, Sales Manager Americas.

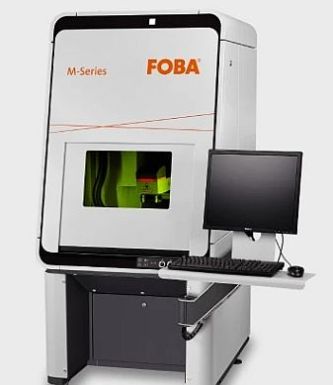

FOBA's M2000 laser marking workstation features an integrated camera situated directly in the laser head, which enables automated part detection and mark alignment. "Our laser solutions enable marking results of high precision with superior ease-of-use and speed," says Kniptash.

Laser marks can be applied on any kind of medical products like stainless steel surgical instruments, titanium implants or plastic items for multiple use.

Besides its M-series stand-alone laser marking workstations, FOBA also develops and supplies marking systems for manufacturing line integration. FOBA's three-step marking process includes precise mark alignment, and the pre- and post-marking validation of parts and of marking results. This helps manufacturers to apply marks of high contrast and durability, like UDI codes, while achieving zero waste and a maximum of efficiency.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::